Process Safety

- HAZOP Study

- Hazard Identification and Risk Assessment (HIRA) Study.

- Quantitative Risk Assessment (QRA)

- Failure Modes and Effects Analysis (FMEA)

- Process Safety Management (PSM)

- Gas Dispersion Modelling

A. HAZOP Study

- Optimize operational safety and efficiency with our Hazards and Operational Procedures Study (HAZOP)

services as per IS 15656 : 2008 standards.

- We specialize in conducting comprehensive HAZOP studies to identify and mitigate potential hazards in your

industrial processes.

- Our experienced team will analyse your operations, systematically identify deviations and propose effective

control measures.

- We offer a tailor made solutions such as: training the HAZOP team, hand held guidance for conducting the

HAZOP study as an external support with our unique HAZOP tool to generate a professional HAZOP report.

- With our HAZOP service, clients can achieve improved safety protocols, reduced operational risks, and

enhanced compliance with regulatory standards.

B. Hazard Identification and Risk Assessment (HIRA) Study

- Enhance operational efficiency and foster a culture of safety within your business by conducting a HIRA study as per standards.

- Our experienced team will offer a valuable support and guidance in conducting a Hazard Identification and Risk Assessment study for the plant, engaging plant personnel after training them.

- HIRA report will identify all the Hazards and Risks in the plant and also list down all the significant hazards of the plant which needs a suitable action plan

- We guide our clients in developing suitable control measures for effective mitigation of all the significant hazards identified in the plant.

- By partnering with us, our clients can achieve a safer work environment, reduce the likelihood of incidents, protect their employees, assets and compliance with regulations.

C. Quantitative Risk Assessment (QRA)

- Risk assessment study or Risk analysis study is conducted in a project or process, in order to implement appropriate control measures to prevent all incidents / accidents and the potential environmental impacts

- We also conduct Qualitative and Quantitative risk assessment studies meeting the client requirements and as per IS 15656 : 2008 standards.

- Our services include, a professional training to the plant risk assessment team, site survey by our EHS experts, and hand held guidance for conducting the analysis to assessment by the plant team.

- We also provide an unique risk assessment tool, to conduct the study and also generate a professional Hazard and Risk analysis report for the plant as per standards

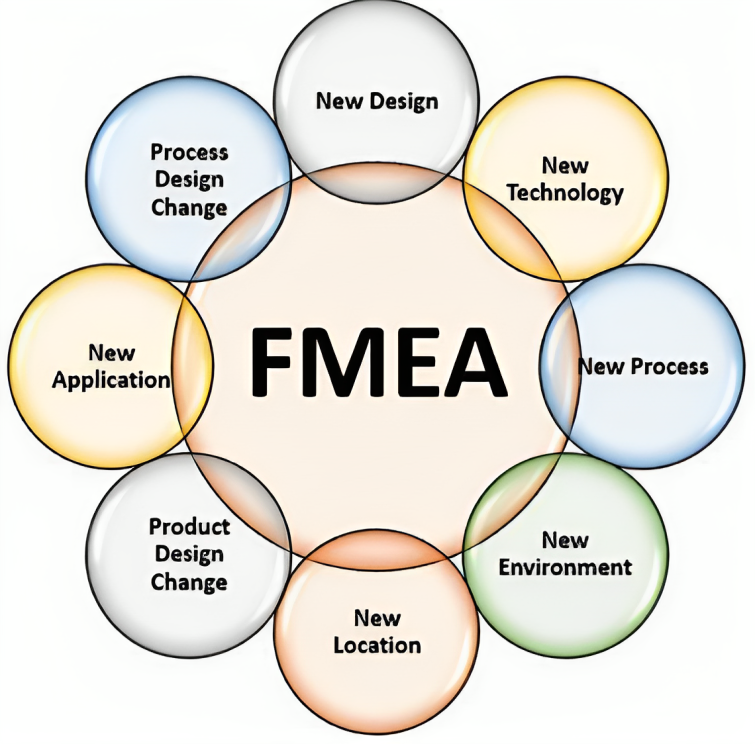

D. Failure Mode Effects Analysis (FMEA)

- FMEA is a problem prevention technique for identifying or investigating potential failure modes, related causes and effects in equipment, processes and systems as per IS 15550: 2005 standards.

- It is one of the method of reliability analysis intended to identify failures, having significant consequences on the system performance.

- FMEA study determines the relationship between the element failures and all the system failures, malfunctions, operational constrains and the degradation of the performance integrity.

- Our services include, a professional training to the FMEA assessment team, site survey by our EHS experts, hand held guidance for conducting the FMEA study by the plant team, we also provide an unique FMEA assessment tool, to conduct the study and also generate a professional FMEA report for the plant as per standards.

E. Process Safety Management (PSM)

- We specialize in providing comprehensive Process Safety Management (PSM) services to businesses across various industries.

- With our expertise and experience, our clients can achieve enhanced safety, reduced, and improved operational efficiency. Process safety management (PSM) is a systematic analytical tool for preventing the release of highly hazardous chemicals and including the hazard contour mapping / dispersion modelling for hazardous chemical releases, using software modelling techniques.

- Hazardous chemicals include toxic, reactive, explosive and highly flammable liquids and gases. PSM is a comprehensive management Process that aims to decrease the number and severity of incidents relating to highly hazardous chemicals.

- Our PSM support elements include the professional assessment of the process area / work place health and safety assessments including the process safety documentations.

- We Evaluate the status of existing design controls and adequacy of the safety procedures followed, management of change procedures and compliance to legal regulations.

F. Gas Dispersion Modelling

- Enhance safety and risk management through our Gas dispersion modelling service.

- Our Gas dispersion modelling service, offers a reliable and accurate assessment of the potential dispersion of hazardous gases in their facilities to the surrounding areas.

- By opting for our service, clients can gain valuable insights into potential risks, make informed decisions regarding safety measures, and develop effective emergency response plans.